What is CNC machining?

CNC machining, or Computer Numerical Control, is a modern method of manufacturing high-precision and repeatable components. By using advanced computer-controlled machines, it is possible to create products with complex shapes and dimensions that are unattainable with traditional production methods. In recent years, CNC machining has gained significant popularity in various industries such as automotive, aerospace, and medical. In Poland, more and more companies are opting for these services, with one of the market leaders being Instal Chemik, which offers professional CNC machining services.

Types of CNC machining

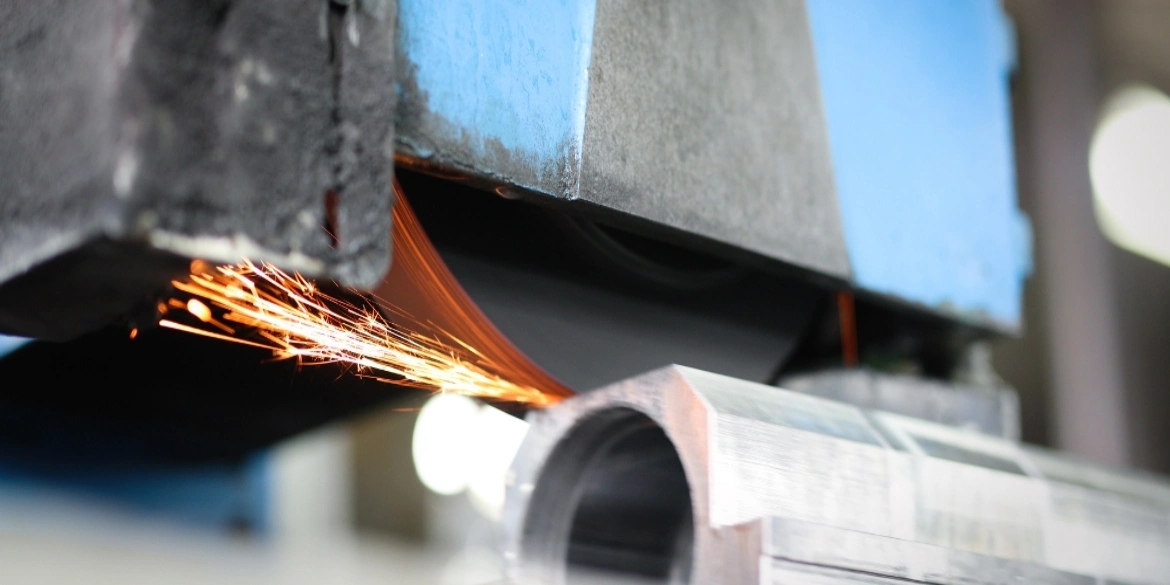

CNC machining can be performed on various types of machines and materials. The most popular ones include CNC milling, CNC turning, laser cutting, and electrical discharge machining. CNC milling involves removing layers of material using milling cutters - cutting tools of various shapes and sizes. CNC turning is the process of cutting material using lathe tools, while laser cutting and electrical discharge machining rely on light or electrical energy to precisely cut materials. Each of these methods has its advantages and applications, so it is advisable to consult experts to choose the right technology for a given project.

Advantages of using CNC machining services

One of the main advantages of CNC machining services is their extraordinary precision and repeatability. With computer-controlled machines, it is possible to produce components with dimensions and shapes that match the design with a very small margin of error. Additionally, CNC machining achieves high-quality surface finishes, which is particularly important for high-precision components such as automotive or medical parts. Another advantage of CNC machining is the speed of order fulfillment - modern CNC machines can operate 24 hours a day, reducing production time.

Choosing the right CNC machining service provider

To achieve the best results, consider several factors when selecting a company offering CNC machining services. Firstly, check the experience and references of the provider - Instal Chemik boasts many years of market presence and numerous satisfied customers. Additionally, pay attention to the machine park and staff competencies - high-quality CNC machines and skilled personnel are crucial for obtaining precise and durable products. It is also worth checking if the company offers technical support and advice on selecting the appropriate machining technology.