Preparation and Cleaning

Powder coating is effective only when appropriate conditions are created for it. An essential and very important stage of the entire process is preparing the surface for painting.

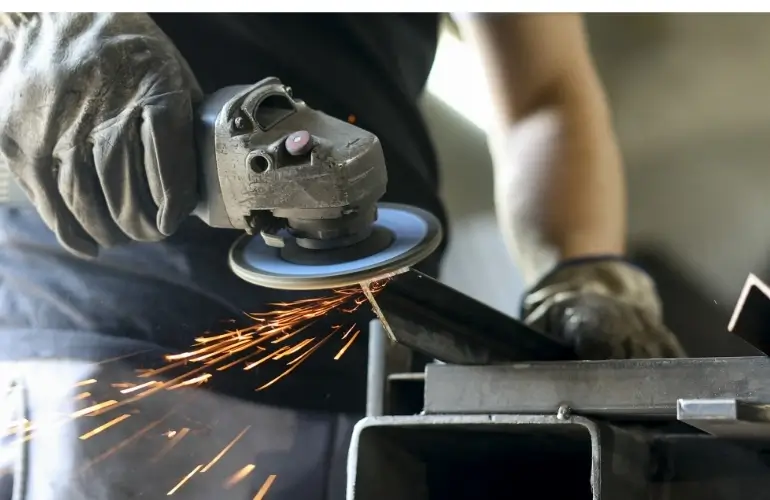

Depending on the type and condition of the surface to be painted, a series of cleaning operations are carried out, such as degreasing, removing unevenness or burrs, removing various types of contaminants, smoothing the surface, sandblasting, drying, dust removal, etc. Preparation for painting aluminum, preparation for painting steel, or preparation of black steel is an essential process before powder coating.

We offer our clients preparation for painting black steel, galvanized steel, and aluminum. This includes abrasive treatment (shot blasting), degreasing, and pickling, followed by initial rinsing, rinsing, drying, painting, and curing.

It is important to remember that even the use of the best powder paints will not produce the desired effect if the surface to be painted is not properly cleaned beforehand. Improperly or only partially prepared surfaces for painting significantly reduce the adhesion of the coating to the substrate, decrease surface smoothness, and cause the development of sub-coating corrosion.

We perform degreasing of metals – degreasing aluminum, degreasing black steel, degreasing galvanized steel – and sandblasting of sheets in our plant in Pleszew, Wielkopolska, about 100 km from Poznań.

Factors Affecting the Quality of Painting

The quality of powder coating depends on many factors. The most important of these are:

- Proper surface preparation,

- Use of appropriate powder paints,

- Quality control.

All these elements influence the durability of the obtained coating and the final aesthetics of the finished product. In addition, the experience of the personnel, the precision of the work performed, and the use of modern technologies are also important.

Types of Surface Preparation

Depending on the needs and exact client requirements, there are several methods of preparing the surface for powder coating. These include sandblasting (shot blasting), chemical etching, or mechanical treatment. Each of these methods has its specific application and final effects. The choice of the appropriate method depends on the type of material, its condition, and the client's expectations.

Choosing the Appropriate Preparation Method

Choosing the right surface preparation method is crucial for achieving the best results. When selecting material preparation methods for painting or powder coating, the type of material, its condition, and the client's requirements must be considered. A well-chosen method ensures the durability and aesthetics of the coating. It is worth consulting specialists who will help choose the best solution for a given case, considering the material's specifics and the client's expectations.

Quality Control

We make every effort to deliver the highest quality products to our clients, which is why we rigorously check every element we produce according to quality control principles developed over the years. Our products undergo a long, thorough inspection for dimensions, cleanliness, and durability. Non-compliant products are reworked.