CNC Machining in Gdańsk

CNC machining is a modern method of manufacturing elements from various materials that is gaining increasing popularity in the industry. Instal Chemik specializes in providing CNC machining services in Gdańsk and many other locations in Poland. We offer our clients high-quality execution and timely completion of all entrusted orders.

What is CNC Machining?

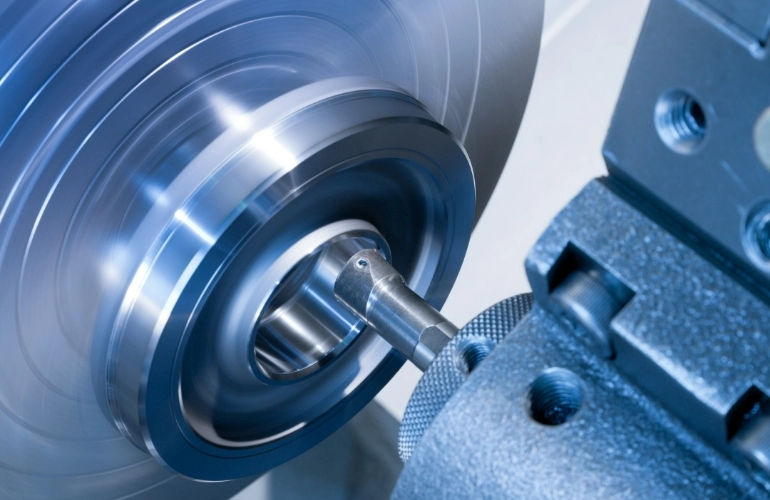

CNC (Computer Numerical Control) is a technology for controlling machines via a computer. CNC machining involves the automatic shaping of various types of materials. With CNC machining, it is possible to create various constructions from metals, wood, or plastics. All work performed with these materials is created according to a pre-programmed pattern. This allows for obtaining precise and repeatable elements of complex shapes.

CNC machining is a technology that has revolutionized the manufacturing industry. It is a process where a numerically controlled machine performs precise cuts and shapes on various materials. CNC machining in Gdańsk is extremely accurate, fast, and repeatable, making it an ideal solution for series production. Unlike traditional machining methods, such as milling or turning, CNC machining is fully automated, minimizing the risk of errors and increasing production efficiency. Our offer includes comprehensive CNC machining of metal parts on numerical and conventional machines according to the specifications or drawings provided by the client.

What are the Advantages of CNC Machining?

In recent years, CNC machining has been gaining increasing interest among our clients. As one of the leading providers of such services in Poland, we operate in many cities and offer CNC machining services not only in Wrocław. Currently, our clients can also take advantage of our CNC machining services in Łódź, Kalisz, Konin, and many other cities. The main reasons for the high interest in these services are:

- Precision and repeatability – CNC machining allows for obtaining elements with very high accuracy and their repeatability in subsequent productions.

- Speed – the automation of the machining process makes it much faster than traditional methods.

- Flexibility – thanks to the ability to easily change the control program, CNC machining allows for quick adaptation to changing customer requirements.

- Material savings – precise machine control minimizes the amount of production waste.

Services Offered by Instal Chemik

Our company offers a wide range of CNC machining services in Gdańsk. We have a modern machine park that allows us to handle the most complex orders. Our services include turning, milling, drilling, grinding, and electroerosion machining. By using the latest technologies, we can ensure the highest quality of our services and short lead times. Experience and knowledge allow us to handle even the most complex projects, always with attention to the smallest details.

Instal Chemik offers a wide range of CNC machining services. In our company, you can also take advantage of services such as:

- CNC Milling – involves shaping material using a numerically controlled milling machine. Used for producing elements of complex shapes and dimensions.

- CNC Turning – material machining using a numerically controlled lathe. Allows for obtaining precise elements with various profiles.

- Laser Cutting – a CNC machining method involving cutting shapes from materials using a laser. Mainly used for machining sheets and plastics.

- CNC Engraving – a technique that allows for applying permanent markings on material surfaces using numerically controlled machines.

By choosing to work with Instal Chemik, clients can expect professional advice, an individual approach to each order, and timely completion of entrusted tasks. Thanks to many years of experience in CNC machining and a modern machine park, our company can handle even the most demanding projects.

The Process of CNC Machining Services in Gdańsk

Using our services is very simple. Just contact us by phone or email to discuss the details of the order. Specialists are at your disposal, ready to answer any questions and advise on the best solutions. After detailing the specifics, we prepare a preliminary quote and work schedule. Then, after the client approves the conditions, we proceed with the order. Throughout the process, we maintain constant contact with the client, informing them of the progress. Our goal is to ensure complete satisfaction and meet the expectations of our clients.